|

| 伸缩蝶阀 |

用途User

本蝶阀适用温度≤80℃,用于石油、化工食品医药轻纺、造纸、电力、给排

水、气体管路上,作调节流量和截流介质的作用,具有补偿管道热胀冷缩的功能。

This butterfly valve,with the suitable temperatu re as=80℃,is used for the pipeline of petroleum,chemical,food,medicine,ight&textile,paper-makin9,water supply and drainage,gas for the flow adjustment and medium cut-off and holds the function to compensate heat-expansion cold-contraction of the pipeline

特点Characteristic

1、设计新颖、合理、结构独特、重量轻、操作方便、起闭迅速。

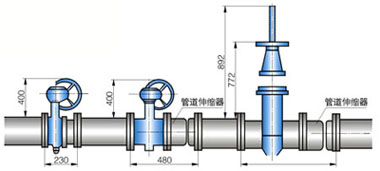

2、本伸缩蝶阀既能起到调节流量和截流作用,又能补偿管道温差,所产生的热胀冷缩功能,同时也便于安装和拆卸,为一阀多用产品。

1 Brand-new and reasonable design,unique structure,light weight,easy operation,quick open-close.

2 This telescopic butterfly valve can act as flow adjustment and cut-off and also compensate the heat-expansion cold-contraction of the pipeline caused due to temperature difference and is conveniently mountable and removable,as an one-valve muIti-purposes product

安装注意事项Precautions in installation

1、本蝶阀安装前必须清洗内腔杂物。

2、本阀可有一定范围内伸缩,安装前必须松开伸缩部位的密封垫压盖,然后待本阀门与管道所需要的长度后,再锁紧伸缩密封压盖。

1 Clear out the impurities inside of the internal cavity before to install this butterfly valve.

2 This valve is stretchable in a certain range and,before installation,the sealing pad of the stretching part shall be loosened and,then,whlength is set for both valve and pipeline,tightened.

|

|

| 名称Name |

材料Material |

| 阀体body |

铸铁、球墨铸铁、铸钢、不锈钢 Cast iron,ductile iron,cast steel stainless steel |

| 阀板Disc |

铸铁、球墨铸铁、铸钢、不锈钢 Cast iron,ductile iron,cast steel stainless steel |

| 阀杆stem |

2Cr13、不锈钢衬 Stainless steel lined |

| 密封圈seat |

耐磨橡胶、丁腈橡胶等wearable rubber,NBR etc. |

| 填料packing |

丁腈橡胶V型垫、柔性石墨V-type pad of NBR,flexible graphite | |

|

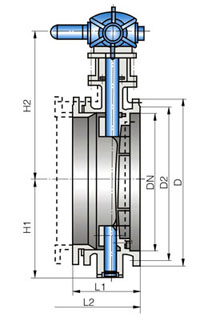

法兰连接尺寸和主要外形尺寸Flange size and main dimensions

| 公称通径DN |

L |

L2 |

L1 |

D |

D |

Z-d |

H1 |

H2 |

| 50 |

158 |

168 |

178 |

165 |

125 |

4-19 |

80 |

155 |

| 60 |

164 |

174 |

185 |

185 |

145 |

4-19 |

80 |

155 |

| 80 |

168 |

178 |

200 |

200 |

160 |

8-19 |

97 |

173 |

| 100 |

181 |

193 |

220 |

220 |

180 |

8-19 |

110 |

220 |

| 125 |

196 |

203 |

250 |

250 |

210 |

8-19 |

125 |

255 |

| 150 |

198 |

213 |

285 |

285 |

240 |

8-23 |

143 |

258 |

| 200 |

213 |

228 |

340 |

340 |

295 |

8-23 |

170 |

310 |

| 250 |

230 |

242 |

395 |

395 |

350 |

12-23 |

200 |

355 |

| 300 |

241 |

258 |

445 |

445 |

400 |

12-23 |

225 |

380 |

| 350 |

256 |

278 |

505 |

505 |

460 |

16-23 |

253 |

422 |

| 400 |

287 |

312 |

565 |

565 |

515 |

16-28 |

281 |

486 |

| 450 |

295 |

325 |

615 |

615 |

565 |

20-28 |

308 |

497 |

| 500 |

310 |

330 |

670 |

670 |

620 |

20-28 |

335 |

560 |

| 600 |

343 |

364 |

780 |

780 |

725 |

20-31 |

390 |

715 |

| 700 |

394 |

414 |

895 |

895 |

840 |

24-31 |

483 |

782 |

| 800 |

405 |

428 |

1015 |

1015 |

950 |

24-34 |

543 |

882 |

| 900 |

410 |

435 |

1115 |

1115 |

1050 |

28-34 |

606 |

925 |

| 1000 |

530 |

560 |

1230 |

1230 |

1160 |

28-37 |

655 |

1000 |

| 1200 |

570 |

602 |

1455 |

1455 |

1380 |

32-40 |

778 |

1087 |

| 1400 |

630 |

665 |

1675 |

1375 |

1590 |

36-43 |

912 |

1350 |

| 1600 |

720 |

730 |

1915 |

1915 |

1820 |

40-49 |

1032 |

1475 |

| 1800 |

800 |

845 |

2112 |

2115 |

200 |

44-49 |

1154 |

1670 |

| 2000 |

910 |

1010 |

2325 |

2325 |

2230 |

48-49 |

1295 |

1780 |

|

|

|